Selling composite roofing as a permanent solution

July 17, 2025 at 12:00 p.m.By DaVinci Roofscapes.

Using the genuine look of the composite products and their stable, reliable performance as selling points.

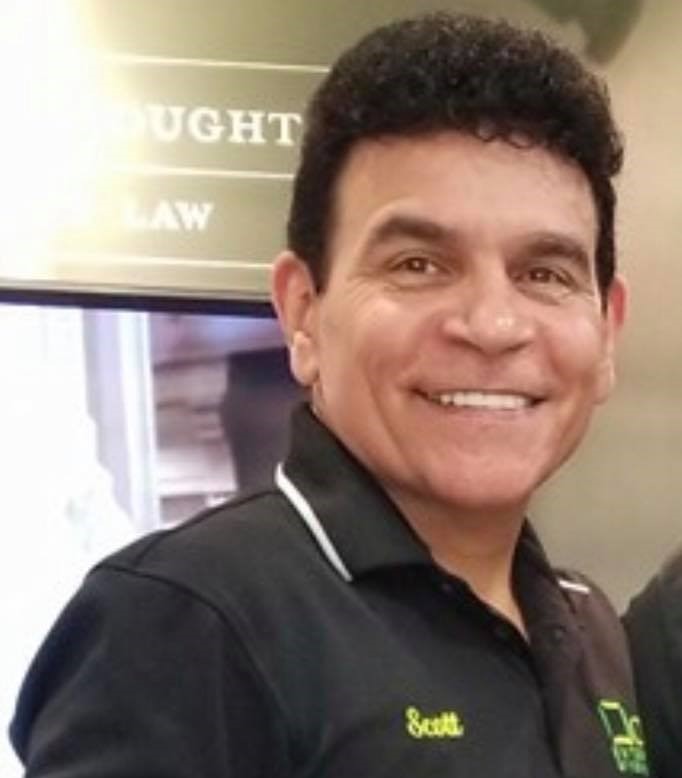

Want to know the “secret weapon” Scott Owen uses to convince his customers to invest in composite roofing? He talks about permanence and stability.

Want to know the “secret weapon” Scott Owen uses to convince his customers to invest in composite roofing? He talks about permanence and stability.

“When making a presentation, I tell people that a properly-installed DaVinci roof system will outlast all of us in this room!” says Scott, LEED AP BD+C, HCRI-R/C, PA and President of Owen Enterprises, Inc. out of Lombard, Illinois. “I make sure that they know it’s the last roof they’ll ever have to install on their home.”

Owen has 25 years of experience installing DaVinci products to back up his enthusiastic support of the composite products. A long-time DaVinci Masterpiece Contractor, his award-winning roofing projects feature both synthetic slate and shake.

Making the sale

According to Scott, offering composite roofing has always provided a permanent solution to his customers. “The synthetic slate profile doesn’t have the breakage issues that you encounter with real slate,” says Scott. “And, the synthetic cedar doesn’t change color or deteriorate like real cedar shakes will over time. The profile the homeowner selects now is what they will have decades into the future.

Selling that consistency and easy care is key. Homeowners don’t want the maintenance hassles associated with real slate or cedar shakes. They love the genuine look of the composite products and their stable, reliable performance.”

Whenever Scott walks into a customer meeting, he’s always bringing samples with him. “Seeing really is believing with this product,” says Scott. “When people see the deep grooves in the DaVinci product along with the colors, it erases any doubts about whether it looks real or not.”

Selling virgin resin

Selling virgin resin

A key selling point that makes Owen Enterprises Inc. recommend DaVinci products over competitive composite products is how the DaVinci product is made.

“DaVinci roofing tiles are made of virgin resin with no recycled content,” says Scott. “That’s really important. The purity of the resin provides strong molecular chains, resulting in proven reliable performance.”

According to the article “Recycled Roofing vs. Virgin Resin,” purer resins have longer lifespans. Virgin resins have only three steps in their life cycle: compounding to injection molding to the finished roofing tile. Recycled (or “second generation”) composite materials start out with the same first three steps, but the finished product may be a plastic yoga mat or milk jug. Once used, it gets recycled, cleaned and ground down. Then it gets injection-molded for a second time into a roofing tile. That’s a six-step process where the resin loses some of its strength.

“There’s one other thing I do to influence potential customers toward a composite roofing sale,” says Owen. “I ask them to look at the DaVinci plant tour video. It’s just 5 minutes long, but it’s educational and impressive. When they see the step-by-step process and understand how the product is made with virgin resins, and the care taken to craft the tiles, everything clicks. Having that sample in their hand at that point brings it full circle and closes the sale.”

Learn more about DaVinci Roofscapes in their Coffee Shop Directory or visit www.davinciroofscapes.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In