Reducing costs on tapered roofs with extended panels

July 1, 2025 at 6:00 p.m.By Hunter Panels.

Learn about the benefits and strategies for using extended panels when working with a tapered polysio system.

Designers and installers working on tapered roof systems often end up utilizing a range of specialty products to reduce the overall cost of building a tapered roof system. From prefabricated options like target sumps and hips, to things like extended roof panels, these specialty components aim to reduce installation time and labor costs. This often outweighs the slightly elevated cost of getting a specialty product and reduces the overall cost of roofing.

So, how do you determine if your project is a good fit for some of these specialty products? It all depends on the unique system you are working with. Keep reading to get some technical advice from the experts at Hunter Panels about designing a tapered roof system in a cost-effective manner.

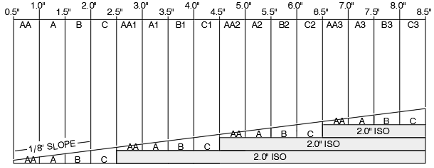

Insulation adhesive costs can be lowered drastically by reducing the number of layers in a tapered profile. Take a standard 1/8” taper profile with a 4-panel repeat:

Using layers of 2.0” flat insulation at every repeat, you’re looking at multiple layers of 2.0” to achieve a 64’ run. It goes without saying that more layers of insulation require more adhesive to properly secure the system. This profile requires 40 panels of application.

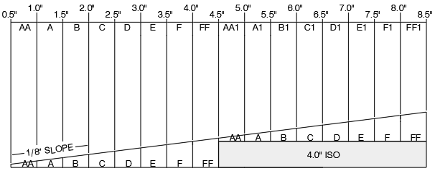

Let’s look at the same 64’ run but using extended panels:

Using this extended panel profile, we’re able to lower the number of insulation layers, thus reducing the adhesive required to adhere the system. This profile requires only 24 panels of application

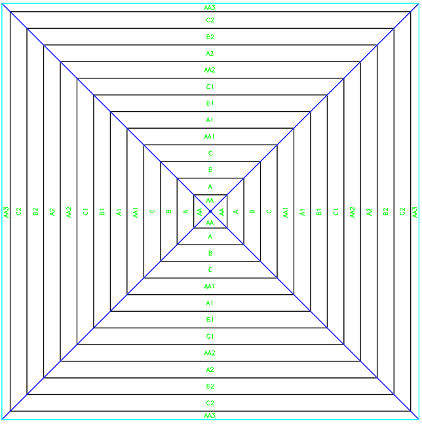

The easiest way to show the benefits of extended panels is a side-by-side project analysis

The design on the left (4-panel repeat) requires 257 squares of application. The design on the right (8-panel repeat) requires 159 squares of application. The cost of insulation for the extended panel option is only $2,300 more than the standard repeat option.

The standout savings in the extended panel design are in adhesive costs. The extended panel option will require 4 fewer tanks of adhesive, yielding a savings of ~$4,800 in adhesive. Regarding labor costs, using fewer layers of insulation means less material handling and field cutting. To top it all off, extended panels create less waste, which not only means fewer dumpster fees for you, but also less material going to waste in landfills!

The above comparisons utilize the 1/8” profile as the example for this article, but extended panel options are available in all profiles (1/8”, 3/16”, 1/4”, 3/8”, 1/2”).

Original article and photo source: Hunter Panels

Learn more about Hunter Panels in their Coffee Shop Directory or visit www.hunterpanels.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In