Leister

For over 70 years, Leister has been the global leader in plastic welding and industrial hot-air applications.

Whether you're welding PVC, TPO or Modified Bitumen membranes, the performance and reliability of our products makes Leister the preferred choice of professional roofing contractors worldwide.

With our cutting-edge technology, high rate of innovation, extensive process expertise, unmatched stability and reliability (not to mention our decades of experience), we work with our qualified employees toward achieving the highest possible product quality.

These standards are the benchmarks for which all product lines that carry our brands, LEISTER, AXETRIS and WELDY, strive to meet. Our innumerable patents and registered designs highlight our development ability and strength in innovation.

Leister Webinar: Say Goodbye to Cables

Experience the Future of Cordless Plastic Welding

Cables, limited mobility, and missing power outlets are daily challenges when working with hot air on-site. In this exclusive webinar, we’ll introduce the solution: the NEXHEAT 300 A-LP cordless, battery-operated heat gun. This mobile hot-air blower offers flexibility, precise temperature control, and intuitive display operation, allowing you to weld, shrink, and shape plastics with maximum efficiency. Whether on a roof, in a tunnel, or anywhere on the construction site, experience cordless freedom during welding.

Webinar Highlights:

- First look at the NEXHEAT 300 A-LP – explore the tool, its components, and how the Bosch AMPShare battery platform gives you ultimate cordless flexibility

- Practical application demos – see how roofing, flooring, and technical textile repairs can be done faster, easier, and completely cable-free

- Key functions in action – ergonomic grip, safe handling, digital display, safety features & precise temperature control

- More efficiency in everyday work – how cordless operation reduces logistical effort, saves time, and gives you flexibility in every situation

Register now for the Leister webinar and experience the NEXHEAT 300 A-LP live!

October 7, 2025, 10:00 AM (New York -EDT) / 09:00 AM (Chicago - CDT) / 07:00 AM (Los Angeles – PDT)

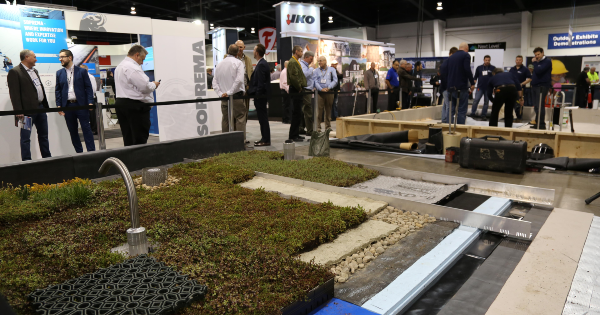

Live at IRE 2025!: Leister

VACUUM PLATE 100-LP

The VACUUM PLATE 100-LP from Leister is an easy-to-use, compact and cordless vacuum plate or vacuum bell jar for roofers and swimming pool builders. The universal AMPShare rechargeable battery (18 V) from Bosch with a 7-hour runtime ensures freedom of movement over long distances and immediate readiness for use of the vacuum testing device. Because the plastic plate, the pump and the battery are one unit, the vacuum test bell is compact, 2 kg light and can therefore be transported with one hand.

- Compact, 2 kg light and quiet

- Cordless thanks to AMPShare battery from Bosch

- Transportable with one hand

- Ready for use anywhere and immediately

- Easy to use

Learn more about the VACUUM PLATE 100-LP.

Leister Booth Interview at MRCA 2024!

The VARIMAT 700

The VARIMAT 700 is characterized by its robust construction and ergonomic design. The automatic roof welding machine comes in a sturdy rolling transport case, ensuring convenient and safe transportation to the place of use.

With a dead weight of 37 kg and optional additional weights, the VARIMAT 700 offers high joining pressure for constant process safety when welding thermoplastic sealing sheets and all types of membranes.

VARIMAT 700: benefits at a glance

- Optimized welding performance due to high contact pressure

- Swivel-in mechanism for quick and efficient nozzle insertion

- Visual and audible alarm when leaving the welding window with the Monitored Welding Assistant

- Flexible voltage selection between 230 V and 400 V

- Removable weights for easier transportation

- Triangular design ensures directional stability

- Sturdy rolling transport case for perfect device protection and ergonomic transportation

- LQS (Leister Quality System) for quality reporting

- Tried and tested welding recipes

- High welding speed

- LED light

Introducing the UNIDRIVE 500 - Roof Welding Close to the Edge Made Easy

The new UNIROOF AT/ST roof welder is your flexible partner for welding thermoplastic roofing membranes on flat or pitched roofs (up to 30°).

Thanks to its slim design and construction, as well as the movable transport axle converting of the machine is no longer needed. Now, you can effortlessly weld close to the edge (to 100 mm ) at the parapet or on the parapet and as easily in narrow circumstances.

The UNIDRIVE 500 closes the gap between manual and automatic welding in a small, 9.9 lbs. lightweight and easy-to-handle semi-automatic hot-air welder.

Radius welds quickly and efficiently with the UNIROOF AT / ST. Pipe collars can be welded easily and quickly with the flexible axle of the UNIROOF AT / ST. Weld roofing membranes up to three times faster than hand welding with the UNIDRIVE 500. It's rotating nozzle and reversible drive makes UNIDRIVE 500 ideal for welding close to the edge and in tight spaces, either on or at the roof parapet, flashing wall, edge and curb details, as well as horizontal and vertical surfaces. The tool is equipped with three handles to provide ultimate welding comfort and balance. In addition, the UNIDRIVE 500 can be easily operated via its digital display.

-

Reliable: Ergonomic handles for balanced pressure and comfort while welding

-

Fast: Up to three times faster than manual welding

-

Versatile: Rotating nozzle and reversible drive for dual-direction welding

-

Practical: Compact and lightweight at 9.9 lbs.

-

Economical: Low maintenance due to its brushless motors

-

Intuitive: Simple user guidance and operation via digital display

-

No converting: Thanks to the movable transport axle the UNIROOF masters welding closte to edge at or on top of the parapet.

-

Swiss Quality you can rely on: Field-tested design for ergonomic handling, flexible relocating and optimal machine guiding.

-

The direct-driven, maintenance-free pressure wheel [drive motor integrated in pressure wheel] leads to clearly optimized overall performance and is easy to service.

-

Greater efficiency at construction sites: The new UNIROOF class brings an additional 38% (ST) to 66% (AT) higher welding performance compared to similar machines.

-

Welding roof structure profiles with a special profile kit.

Radius welding with UNIROOF AT/ ST

Single Ply Roof Membrane Welding with the LEISTER Triac ST

The Leister Triac ST plastic welding tool being shown in use on the roof for single ply membrane welding

The TRIAC AT shows, at the push of a button, the current mains voltage (quality checking before the welding process)

The built-in motion sensor knows when the tool is not in operation and reduces the blower level to its minimum speed, which means up to 40% energy saving and noise reduction

Handiness, reliability and versatility are the key arguments in favor of the TRIAC ST. Its two-component handle gives users perfect grip, while the low weight of less than a kg ensures optimum weight balance. The innovative motor and turbine design, combined with the heating element familiar from the TRIAC AT, enhance the value even more. More than 80 nozzles fit onto the TRIAC ST; these are also compatible with the TRIAC AT and TRIAC S.

-

100% Swiss made quality

-

60 years of expertise in making hot-air tools – brought together in the new TRIAC ST

-

The sturdy, professional hot-air tool that weighs less than 1 kg/2.18 lbs

-

Functional design: two-component handle grip and optimum center of gravity ensure ergonomic working

-

Quick clean air filters

-

Automatic carbon stop (collector protection) and heating element protection

Latest Promotions and Rebates

Say Goodbye to Cables – Experience the Future of Cordless Plastic Welding

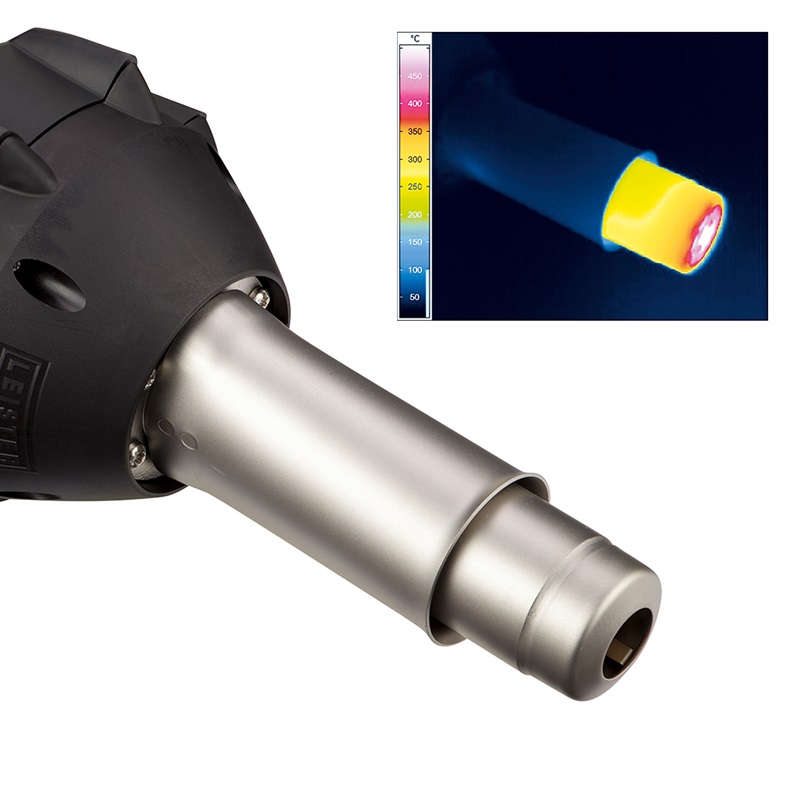

The NEXHEAT 300 A-LP wireless heat gun provides precise temperature control from 50 to 500 °C (122 °F to 932 °F) – adjustable in 5 °C (41 °F) increments. The air volume is adjustable in five stages and makes the device ideal for welding, shrinking or deforming plastics. The battery ...

View Promotion

Latest Canada Content

ROOFTech 2023 is Coming Soon!

By Evelyn Witterholt.

Canada’s dedicated trade show for the construction industry is right around the corner.

The 2023 ROOFTech Show is approaching fast! This trade show, dedicated to the Canadian construction industry, will take place on April 4-5, 2023 in Toronto, Canada at the International Centre. Register for tickets today ...

View Content

Latest Podcasts

Small Innovations for Big Improvements

In this Roofing Road Trips® episode, Karen Edwards talks with Dave Nordentoft of Leister about the real-world decisions behind choosing the right tools for service and repair work. What makes one welding gun better than another? How does a vacuum plate actually help roofers on the job? And what’s the ...

Listen to the Podcast

Latest Heat Welding Tech and Innovations

Tune into RoofersCoffeeShop’s RLW recorded live from the International Roofing Expo (IRE) with Heidi J. Ellsworth and guests Dave Nordentoft and Brittany Wykle of Leister. They discuss the latest advancements in heat welding technology for the single-ply roofing market, focusing on innovations that improve efficiency and quality. The conversation highlights ...

Listen to the Podcast

Dave Nordentoft - Redesigned VARIMAT

S6:E10

In this exciting episode of Roofing Road Trips, Heidi J. Ellsworth sits down with Dave Nordentoft from Leister to talk about the brand-new, redesigned VARIMAT automatic heat welder. Dave gives us a brief history of the VARIMAT and then dives right into the improvements made in this new version. ...

Listen to the Podcast

Latest Webinars

Cordless hot-air blower: NEXHEAT 300 A-LP by Leister

Cordless, flexible, efficient: With the NEXHEAT 300 A-LP cordless hot-air blower, you can weld, shrink and deform plastics anywhere – no power outlet required. Discover in the webinar how this tool simplifies and streamlines your daily work.

Cordless freedom on the jobsite

Cables and missing sockets often hinder welding, shrinking or deforming ...

Watch the Webinar

Read Listen Watch - Educational Content

Latest Heat Welding Tech and Innovations

Tune into RoofersCoffeeShop’s RLW recorded live from the International Roofing Expo (IRE) with Heidi J. Ellsworth and guests Dave Nordentoft and Brittany Wykle of Leister. They discuss the latest advancements in heat welding technology for the single-ply roofing market, focusing on innovations that improve efficiency and quality. The conversation highlights ...

View Content

Buy Online

The NEXHEAT 300 A-LP wireless heat gun provides precise temperature control from 50 to 500 °C (122 °F to 932 °F) – adjustable in 5 °C (41 °F) increments. The air volume is adjustable in five stages and makes the device ideal for welding, shrinking or deforming plastics. The battery ...

Read More

The VARIMAT 700 is characterized by its robust construction and ergonomic design. The automatic roof welding machine comes in a sturdy rolling transport case, ensuring convenient and safe transportation to the place of use. With a dead weight of 37 kg and optional additional weights, the VARIMAT 700 offers high ...

Read More

Leister Technologies, LLC is proud to announce the launch of our new eCommerce store, supporting the online sale of select heat guns, stationary welders, automatic welders and accessories.

Visit leister.store to place your online order today!

Read More

Latest Videos

Leister Video Playlist

For over 70 years, Leister has been the global leader in plastic welding and industrial hot-air applications. Whether you're welding PVC, TPO or Modified Bitumen membranes, the performance and reliability of our products makes Leister the preferred choice of professional roofing contractors worldwide.

See more videos from Leister on their YouTube ...

View Video

View Full Gallery