Why Contractors Choose BUR

By Colin Sheehan, RCS Reporter.

After 160 years BUR is still a long-lasting, cost-effective and energy-efficient roof system solution.

Bituminous waterproofing has been around basically as long as mankind. Evidence of humans using bitumen for waterproofing dates back as far as six millenniums BC, or over 8,000 years. Incredibly, a 5,000-year-old water tank from the Indus valley in Pakistan uses the same designs of modern dams with naturally occurring bitumen.

If it’s not broken, don’t fix it. While technological evolution has reaped many beneficial results, some things don’t need a weekly update. BUR (Built Up Roof) membranes have remained the most used system for over 160 years for a reason: they are dependable, adaptable, cost effective and a sustainable option for contractors.

Unbeatable lifecycle

BUR’s near indefinite lifecycle is extremely cost effective and more than makes up for initial installation costs that may exceed that of cheaper systems. Additionally, BUR’s resistance to hail damage, wind uplift damage and mold and mildew decay makes BUR a great option for those thinking long-term.

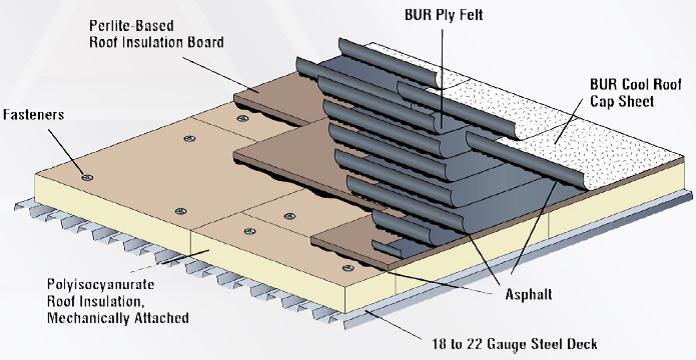

BUR incorporates alternating layers of asphalt and ply sheet, creating a robust and stable surface to stop water leakages. It’s redundancy also makes a repair job simple and regular maintenance a breeze. A BUR system can be extended almost indefinitely.

Adaptable to all environments

BUR offers white solvent and water-borne asphalt coatings, elastomeric coatings and highly reflective cap sheet options to reduce the cooling load on commercial buildings. A BUR roof is often the most energy-efficient option in climates where heating and cooling costs are more evenly split over a year. BUR roofs are also an adaptable option, as contractors can choose varying levels of reflectivity specific to each building and its surrounding environment.

The United States government, which has more low-slope buildings throughout the world and in varying climate conditions than any other organization, utilizes BUR membranes for their long-lasting high quality and corresponding cost efficiency.

A BUR system is safe

In the past asphalt has gained attention for emitting possible cancer-causing fumes. However, it is now known that the chances of a person with a 45-year career working in an asphalt plant getting cancer due to asphalt fumes are eight in 1 million. To help put things into perspective, the likeliness of getting hit by a meteor is 32 in 1 million. And new technology allows for a low smell option for BUR roofs.

Trusted quality

It may be hard to believe, but many major asphalt manufacturers place used motor oil in their asphalt as a filler to cut costs. The problem is not recycling used motor oil, in fact motor oil can be re-used as helpful motor-related lubricants. The problem is that used motor oil – or new motor oil for that matter – has no place in an asphalt mixture. This would be like making a cake with juice instead of milk. The end result may look similar, but the internal components are completely off.

RCS partner United Asphalts uses 100% asphalt flux and never adds cheap fillers. If you’re curious about which manufacturers utilize used motor oils, you can look at the MSDS forms on their websites which tell what exactly is in their mixture.

Advancing asphalt

Extreme weather is an increasing phenomenon in today’s world and the demands for better materials and systems that can withstand the most extreme weather conditions are becoming more frequent. To meet these demands, United Asphalts created ENDURAflex HT SEBS.

UA has been at the edge of asphalt technology and has been a contributing member in its evolution. The ENDURAflex HT SEBS modified asphalt system was made with the needs of the future in mind, like increasing temperatures and natural disasters. SEBS modified asphalt delivers the waterproofing and weatherability of traditional asphalt with the superior strength, resistance to UV degradation and quick elastic recovery of the SEBS.

The SEBS technology provides the best performance in extreme weather conditions and has high tensile elongation to allow movement without breakage. This system is also ideal for vegetative and inverted roof systems.

While roof designs, products and materials, application techniques and environmental standards all change and develop, BUR remains a solid option for contractors and building owners everywhere.

Learn more about United Asphalts in their RoofersCoffeeShop® Directory.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In