Unique Innovation Leads to Roofing Granule Success

By Karen L. Edwards, RCS Editor.

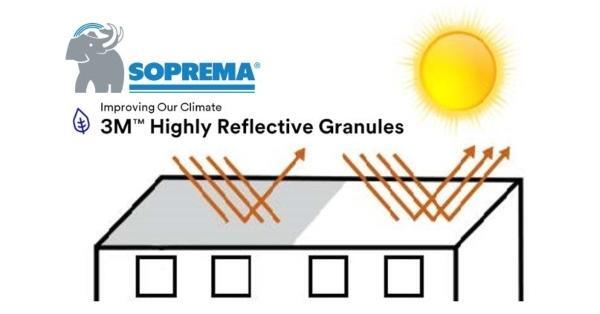

3M innovation and SOPREMA marketing has brought a highly reflective roofing granule to low-slope roofing.

In the Fall of 2019, I had the chance to visit 3M along with members of the Roofing Technology Think Tank (RT3) to learn about the innovations 3M has brought to the world. We toured their Customer Innovation Center and heard from team members how the company continues to develop and test products and solutions that can make the world a better place. We finished our day-long visit in the Roofing Innovation Center, where manufacturers can test granule color blends and develop new color mixes for their lines of shingles.

Most people don’t usually put roofing granules and innovation in the same sentence. It’s just ceramic coated rocks, so what would be so innovative about that? Turns out there is a lot of innovation going on when it comes to roofing granules. 3M scientists were behind the development of the copper roofing granule that resists black streaks on roofs, the cool roofing granules with solar reflectance properties and the smog reducing granules which was recognized as a Best Invention of 2018 by Time magazine.

When SOPREMA brought their new-generation SG highly reflective cap sheets to market last year that feature the 3M™ Highly Reflective line of granules, we wanted to learn more about how the special granules were developed and what makes them different from classic white granules. I spoke with Maureen Kavanagh, Laboratory Manager for 3M Industrial Mineral Products Division, about the granule-making process and innovation behind the highly reflective granules.

Maureen shared that rock is mined from one of four different locations throughout the U.S. and then subjected to a crushing and screening process that results in a specific grade of granule that is topped with a proprietary ceramic coating. “We sell size 11 grade granules to manufacturers of residential shingles and cap sheets because they tend to get better coverage on the asphalt mat,” explained Maureen. “The granules are there to protect the asphalt layer from degrading. Better coverage provides better protection.”

Wanting to offer more eco-friendly roofing solutions, SOPREMA turned to 3M to help them develop a highly reflective granule for their SOPRALENE® SG and ELASTOPHENE® SG line of cap sheets. Maureen said that simply using the classic white granule would not deliver the desired reflectance rating. She explained, “Typically when we coat a granule, the human eye cannot detect whether it is coated 100%. If you look at it under a microscope, it probably has 50-60% coverage on each granule. The more coverage you have, the more expensive it becomes. To achieve higher solar reflectivity, it requires more coating on a particular granule.”

The industry also needed to address the issue of asphalt staining. Classic granules can become stained from the asphalt, causing them to lose reflectivity. Maureen shared that 3M started looking into the concept of highly reflective granules about seven years ago and said that the innovation process can take years to actually come to fruition. “The process can be fairly long,” said Maureen. “We have worked on technologies for years even before our customers have interest in the overall product. We are always looking at trends in the market and asking, ‘what would I want as a consumer, or as a contractor?’ We look at what direction cities are moving toward and thinking how we can help them meet their goals.”

SOPREMA’s interest in developing a cap sheet with the highly reflective granule spurred an exciting innovation by 3M for the asphalt roofing market – especially in California. The granules meet ENERGY STAR®, California Title 24, and Los Angeles Green Building Code standards, delivering a minimum solar reflectance of 0.73.

Maureen said that once a product is brought to market, 3M continues to study performance and lifespan. 3M has an outdoor weathering facility in Houston, Texas where the recently introduced smog-reducing granules are being studied. “We want to know how they weather over time and if they still have the same nitrogen oxide reduction capabilities after many years in the field,” stated Maureen.

“Right now, we are studying the impacts that smog-reducing granules can have on cities; how it can help air quality in cities. We are also looking at how we can combine the smog-reducing capabilities with the highly reflective granules to see if it’s feasible to bring to market.”

Learn more about SOPREMA’s SG line of products featuring the highly reflective granule and request a sample.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In