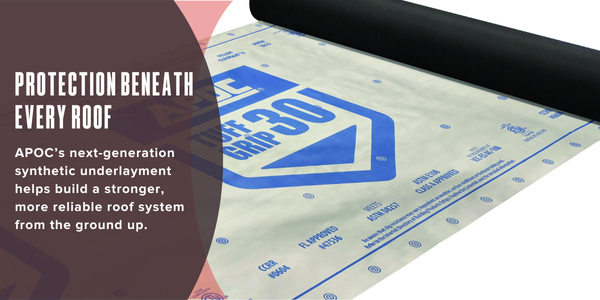

Protection beneath every roof

November 9, 2025 at 9:00 a.m.By Dani Sheehan.

APOC’s next-generation synthetic underlayment helps build a stronger, more reliable roof system from the ground up.

Beneath every shingle, tile or metal panel lies an underlayment – a critical secondary barrier that helps keep moisture out, boosts system performance and ensures long-term durability. In a recent episode of Roofing Road Trips®, Karen Edwards sits down with Gregg Malanga and Dan Roth from APOC to introduce the next generation of underlayment technology, Tuff Grip.

“Your roof cover is the primary layer everyone sees. But if wind-driven rain or moisture gets underneath the shingles, the underlayment keeps it from entering the building,” shares Gregg. Underlayments also help reinforce the roof system’s overall durability and performance, especially in regions prone to extreme weather. Gregg continues, “In northern climates, peel-and-stick products help prevent ice damming, while in coastal areas, they protect against heavy wind-driven rain.

For decades, many contractors relied on 15- and 30-pound felt. But, as building standards and job site conditions have evolved, so have performance expectations. Gregg explains, “The primary reason synthetic underlayments have become so popular is their UV stability. If a roof needs to stay exposed for a few days, like with metal panels or during inspection, synthetic underlayments won’t degrade in the sun or wrinkle when it rains.” Traditional felt can absorb moisture and buckle, leading to tears, leaks and call backs.

Safer, faster and stronger

APOC developed Tuff Grip as a contractor-focused solution – a product that enhances job site safety and simplifies installation without sacrificing performance. “It’s lighter, covers more area and goes down quicker than traditional felt,” Gregg highlights. “Each roll covers about 1,000 square feet, and installation is roughly 33% faster. Plus, it’s got a high-traction surface, so it’s safer and easier to walk on, especially on steeper or slick roofs.”

With decades of experience manufacturing underlayments across the country, APOC designed Tuff Grip as the next generation in its proven lineup, following the success of products like Gator Skin. The company’s goal is simple: to help contractors work smarter, safer and faster while delivering lasting protection that homeowners can rely on.

Purchasing Tuff Grip is also another way to earn rewards through the APOC Contractor Pro Program. “It’s a three-tiered program where contractors can earn up to 2% back on purchases, just by submitting invoices,” Dan explains. “You can redeem points for valuable training, marketing support, free swag and even qualify for an all-inclusive resort trip for our top-tier members.”

From improved walkability to enhanced weather resistance, Tuff Grip delivers the kind of performance today’s conditions demand. Listen to the full episode to learn more about underlayment advantages and how this product fits into APOC’s Contractor Pro Program.

Learn more about APOC in their Coffee Shop Directory or visit www.apoc.com.

About Dani

Dani is a writer for The Coffee Shops and AskARoofer™. When she's not writing or researching, she's teaching yoga classes or exploring new hiking trails.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In