Mastering the art of field cutting – Part 2

April 9, 2025 at 3:00 p.m.By AEP Span.

Why your exposed metal edges might be safer than you think.

In part one of this article series, Mastering the Art of Field Cutting – Part 1, we explored the importance of precise cutting techniques to ensure the durability and aesthetics of metal panels, discussing the risks of improper methods and the best tools for clean, corrosion-resistant cuts. Now, we turn our focus to a common concern among builders and architects: the potential for corrosion at exposed metal edges. The mere mention of exposed metal edges can send shivers down the spine of builders and architects alike, conjuring up fears of premature rust and structural decay. But is that fear justified? When metal roofing panels are properly cut and installed, corrosion at exposed edges is far less of a concern than many believe. Thanks to advanced metallic coatings and the remarkable self-healing properties of ZINCALUME®, those cut edges may be better protected than you realize. Before you let outdated assumptions dictate your roofing decisions, we here at AEP Span explore the science behind cut edge protection — and why you might not need to worry as much as you think.

The misunderstood aspect of cut edge protection

Metal roofing installers and users do not need to be concerned about corrosion at cut edges when field cutting metal panels correctly. While the edge is exposed, the base carbon steel is encased by a metallic coating on both sides. Over time, galvanic action causes zinc compounds in the coating to automatically build up at any cut edges to prevent corrosion. Additionally, when metal is cut in a shearing action, small amounts of the metallic coating can be folded over the exposed base metal to provide additional protection. For particularly harsh environments, consider hemming panel edges to conceal and shield them from exposure. Irregular cutting motions such as sawing or abrasive cutting may introduce impurities to the cut edge or create inconsistent pathways for the metallic coating to encase the cut edge, increasing the risk of corrosion.

The science behind self-healing properties

In service, galvanic action causes zinc compounds to automatically build up at any cut edges or scratches through an electrolytic reaction when water or moisture is present. This process slows the rate at which the surrounding coating is consumed around damaged areas, sometimes referred to as the “self-healing” property of ZINCALUME® coatings.

Superior cut edge protection in severe environments

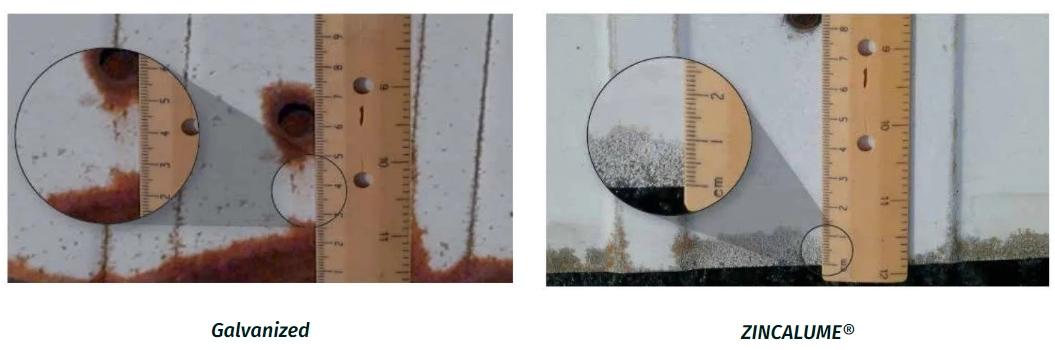

In more severe environments, ZINCALUME® offers superior cut-edge protection. Unlike galvanized coatings, which are purely sacrificial, zinc and aluminum are included. While zinc will corrode preferentially, aluminum acts as a protective barrier, slowing the spread of corrosion and the rate at which this coating is consumed. For additional protection, particularly in harsh environments, consider hemming panel edges to conceal and shield them from exposure.

Are cut and exposed edges a source of corrosion?

The short answer is no. Field cutting metal panels with exposed edges are not a significant source of corrosion. However, this depends on installation and environmental factors. In general, several reasons underpin why exposed edges are not a source of significant concern:

- The zinc in the ZINCALUME® coating acts as a sacrificial layer.

- The self-healing properties of the coating slow down the rate of corrosion.

- Additional protective measures, such as hemming, can be employed in extreme environments.

In summary

In summary, following proper field cutting techniques and using recommended tools will help ensure that your AEP Span metal panels perform as intended and maintain their aesthetic and functional qualities over time. Always consult with a technical services team for specific recommendations and best practices tailored to your project needs.

Original article and photo source: AEP Span

Learn more about AEP Span in their Coffee Shop Directory or visit www.aepspan.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In