Keeping your solar panels and roof safe in snowy conditions

June 27, 2025 at 6:00 p.m.By The Metal Roof Experts™ at S-5!®.

Discover smart strategies for installing snow retention when you have solar panels on your metal roof.

Rooftop snow management is a critical safety issue — especially for metal roofs with solar panels. Without the right snow retention system in place, a snow mass can release unexpectedly, putting people, property and solar arrays at serious risk. The experts at S-5!® are here to break down what every contractor needs to know about snow behavior on metal roofing, how solar panels change the game and best practices for keeping it all in check.

Header image: Solar panels can be a slippery surface in snow country.

First, we’ll explore some basics about the science of snow on metal roofing and smart snow retention strategies. Then, we’ll look at how solar panels affect (and are affected by) rooftop snow accumulation.

What happens when snow collects on your metal roof?

If you live in snow country, you’ve probably seen a rooftop avalanche. This event occurs when a snow mass sheds off a metal roof all at once. Snow loads on a roof can vary widely from as low as 20 psf up to 300 psf and even greater. The result is dangerous – and potentially catastrophic – for people, vehicles, landscaping, property and equipment below.

This image shows the aftermath of a rooftop avalanche released from a metal roof.

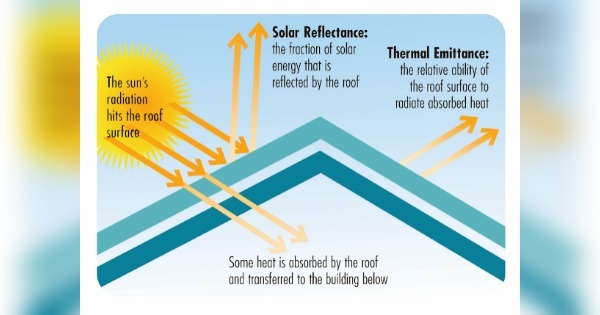

The conditions for a rooftop avalanche begin when snow accumulates on a roof. Initially, the snow is held in place by a frictional (but temperature-sensitive) bond. Compressive forces push downward, compacting the snow blanket. The vector force (sometimes known as a drag load or gravity load) pushes the snowbank toward the eave, increasing its density. When sunlight warms the metal roof surface through the translucent snow, a melt-water sheet forms beneath the snowbank and creates a slippery condition allowing the snow to slide off the roof.

What holds the snow back?

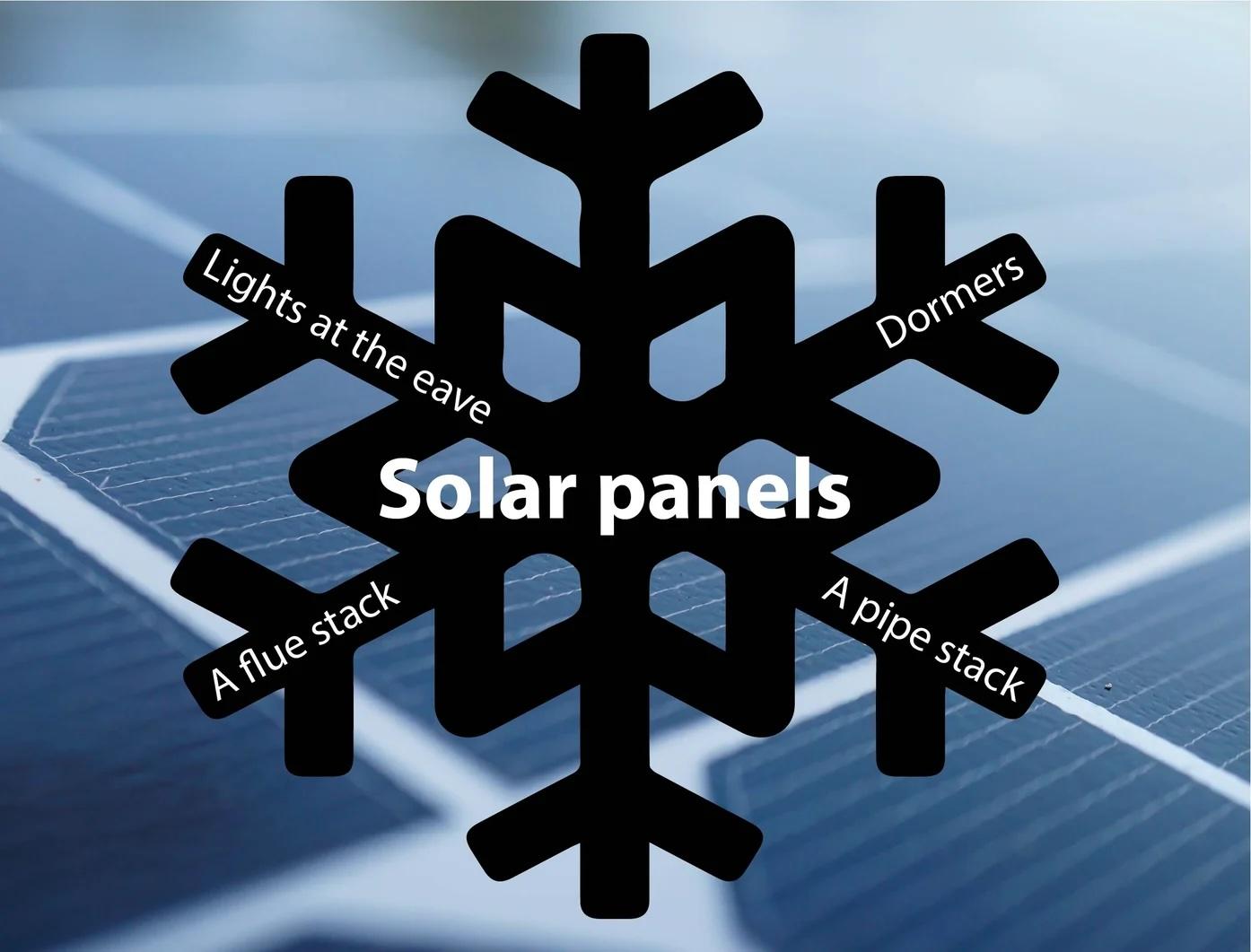

The truth is any rooftop obstruction can create an unintentional snow guard. Obstacles can include items such as:

These rooftop obstructions – including your solar panels – can act as an unpredictable snow retention system.

Snow can accumulate above and on the lower edge of PV modules.

To prevent a rooftop avalanche, you need a reliable system designed to hold the snow safely in place as it melts such as a continuous “snow fence.”

How do you engineer a reliable snow retention system?

The forces of snow on a rooftop can be mathematically calculated, allowing you to properly engineer a snow retention system for any roof. Learn about "Metal Roof Design for Cold Climates" in the Metal Construction Association’s (MCA) White Paper and watch this video to get an overview of how it works.

How does snow affect solar PV panels?

A solar module has a slippery surface, but in many cases, sliding snow can damage modules in addition to presenting hazards beneath the eave. Module frames are not designed to act as a snow retention system capable of resisting drag (vector) loads. This is where an engineered snow retention system can help.

The module frame is damaged and tearing away.

This solar panel was damaged by sliding snow.

First, be sure the module has a design-load rating equal to or greater than the roof design snow load. Module producers generally publish tested loads for a given module in their product information. Typically, this information is found within the module producer’s product manuals. But be certain the published module loads you’re viewing have the appropriate factor of safety applied.

It’s also important to never add a snow retention system supported by your module frames. If this much damage occurred to the module in the photo above with only a 1/8” frame lip holding back the snow, imagine how much damage could happen when a 2 or 3-inch snow retention system is affixed to a module frame. This creates a moment arm adding a “prying” force, which only compounds the problem!

Where should snow guards be installed on a roof with a solar PV array?

Because snow guards need to be placed at the eave where the snow blanket is densest, you may need to sacrifice some space to enable them to work efficiently. So, locate your first row of modules further upslope. Creating space between the lower row of modules and the snow guard at the eave allows snow to accumulate and densify on the roof between the array and the snow guard.

Example of adequate separation space between PV array and snow guards

This distance between the first row and the snow guards can vary depending on the severity of your region’s snow loads and the size of the roof surface. With adequate separation space, lower-profile snow retention systems will generally work. But when the distance between the lower row and the eave cannot be maximized, use a taller snow retention system to restrain the snow mass.

X-Gard™ 2.0's taller profile holds back the snow blanket.

What about tilted-racking systems on a low-slope roof?

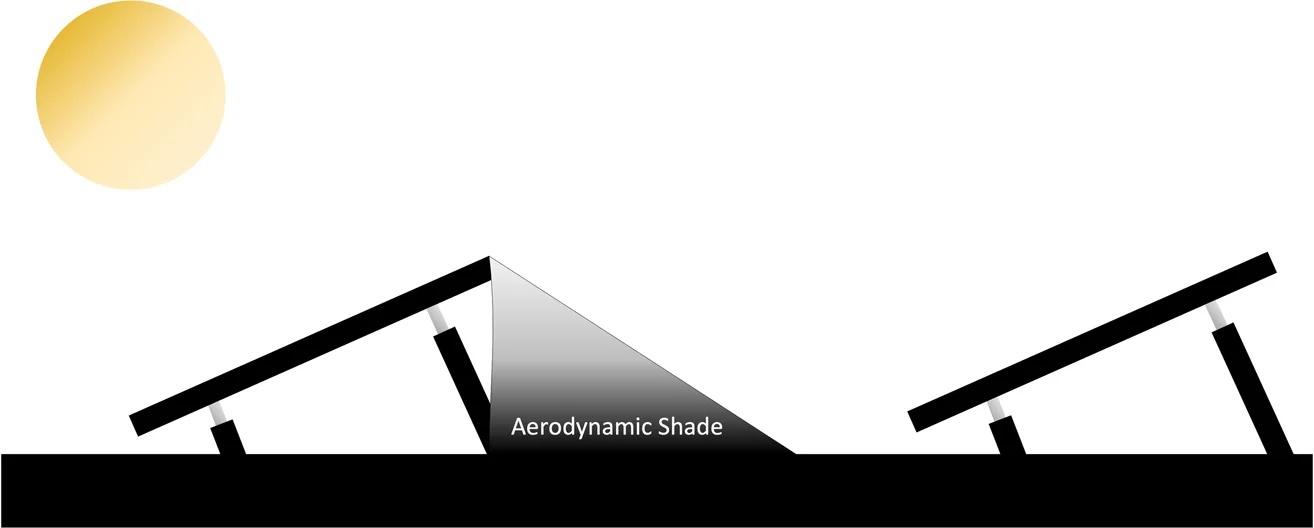

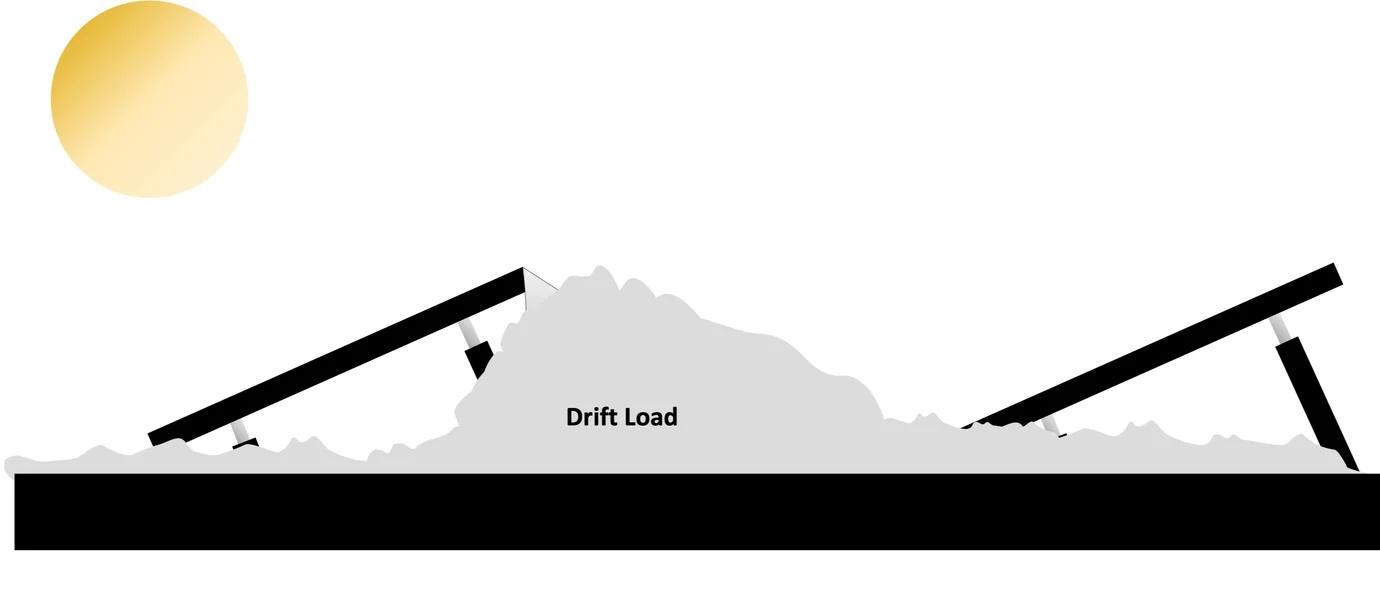

Tilted-racking systems require a space between each row of modules. The space prevents rows from casting shade on each other to maximize the modules’ energy output. But drifting snow and wind-driven snow can stack up in the space behind the titled modules, creating snowdrift loads greater than the roof design snow loads.

The space behind rows of modules creates areas of “aerodynamic shade,” where sunlight cannot reach to melt accumulating snow or ice. Over time, these accumulations can lead to heavier loads than the roof was originally designed to support.

The ASCE library offers recommendations on how to deal with aerodynamic shade and wind-driven snow in “Snow Loads on Solar Paneled Roofs.”

The space behind rows of modules produces areas of aerodynamic shade.

Aerodynamic shade in snow country can create snow drift loads that are greater than roof design snow loads.

How do you make sure you have the right snow guard system for your job?

Snow loads imposed vertically on the roof translate to “vector” forces parallel to the roof surface. These are the forces that need to be resisted by the snow guard system. The vector force can be easily calculated for any roof. They are also forces that the mounting system must endure, so the mounting system must be engineered to resist these forces as well. You need testing by a third-party accredited laboratory to validate that the system can support the vector forces of any individual project.

It’s critical the testing is specific to your actual roof profile, material and gauge thickness, as different project factors yield different results. Look for published results that are readily available so you can verify proper testing was conducted. And double-check to be sure the published results include an appropriate factor of safety. This is the allowable load to be used in design. Many vendors only publish ultimate loads with no safety factory included. When your goal is to prevent thousands of pounds of snow from becoming a rooftop avalanche, having the factor of safety built-in is essential.

Regardless of the chosen system, quality assurance throughout the process is paramount. This includes selecting systems that are engineered and designed for the specific project's conditions, proven through certified testing to withstand the anticipated loads, and manufactured in audited facilities with stringent quality standards. The market for snow retention systems, while offering numerous solutions, has historically lacked comprehensive industry-wide standards, emphasizing the "buyer-beware" nature of product selection. Designers and building owners must therefore exercise due diligence in vetting manufacturers and scrutinizing their testing data, engineering calculations and manufacturing certifications.

Compliance with emerging industry consensus standards, such as the International Association of Plumbing and Mechanical Officials (IAPMO) Evaluation Criteria 029-2018 and adherence to guidelines provided by organizations like the MCA and the International Code Council (ICC) are critical to ensuring the quality and reliability of snow retention systems. The MCA Technical Bulletin “Qualifying Snow Retention Systems for Metal Roofing” is harmonious with EC 029-2018.

Ideas to hold onto

Regions prone to heavy snow create unique situations when it comes to solar PV arrays on metal roofing. Today, we explored:

- The importance of preventing a rooftop avalanche and how to engineer a reliable snow retention system.

- The damaging effects snow can have on solar modules.

- Snow guard placement in relation to solar modules.

- The effect titled-racking systems have on snow accumulations.

- Ways to validate that your snow retention system will support the loads.

- Why complying with emerging standards, such as IAPMO Evaluation Criteria 029-2018, is crucial for system quality and reliability.

Understanding the factors at play with solar panels in snowy conditions allows you to protect both people and property, optimizing the service life of your metal roof and your solar PV installation.

Original article and images source: S-5!

Learn more about S-5! in their Coffee Shop Directory or visit www.S-5.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In