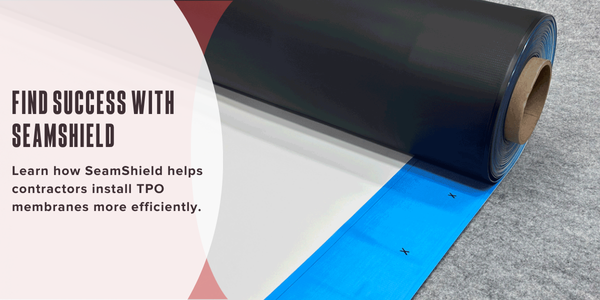

Find success with SeamShield

July 3, 2025 at 3:00 p.m.By Versico Roofing Systems.

Learn how SeamShield helps contractors install TPO membranes more efficiently.

Improve the way you install TPO membranes with the Versico Roofing Systems patented SeamShield ™ technology! SeamShield is an easy-to-remove film that is placed on the top and bottom of seam areas of TPO membranes. It acts as a protective layer that keeps dirt, debris and adhesive overspray from getting into seams. By keeping this area clean, not only are you making your workspace neater, but you are also setting yourself up for success during the welding stage of the installation process.

Sounds promising, doesn’t it? Here’s a closer look at the benefits and features of SeamShield:

SeamShield facts

- Easy-to-remove films that leave a residue-free surface that is ready to weld.

- A 6-inch transparent blue film on the top ply allows overlap lines and fastener marks to be easily seen for installation.

- A 3-inch white film contrasts with the black bottom ply.

- A split top film accommodates both mechanically fastened and adhered installations. The split transparent top film allows plates and fasteners to be installed directly through the film in mechanically fastened installations with a 2.5-inch strip that can be removed when the seam is ready to weld. In adhered applications, the entire top film is removed prior to welding.

- SeamShield clean seams increase seam weld strength versus traditional cleaned seams.

- VersiWeld TPO with SeamShield technology is available in 10’- and 12’-wide sheets in 45-, 60- and 80-mil thicknesses and the standard colors of white, gray and tan.

- Once installed, the film should be removed within seven days.

Contractor benefits

- Enhances productivity by eliminating the time and materials required for cleaning seams.

- Improves ergonomics through a reduction in the time spent bent over during the cleaning process.

- Improves weld consistency by providing a factory-clean seam at the time of welding.

Ideal applications

SeamShield technology is a great addition to any job and is particularly suitable for re-roofing applications where the presence of additional dirt can lead to prolonged cleaning times. Furthermore, it minimizes the need to protect the seam area from excess adhesive in adhered applications, where overspray can prolong cleaning durations.

Original article and photo source: Versico Roofing Systems

Learn more about Versico Roofing Systems in their Coffee Shop directory or visit www.versico.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In