Balancing Building Science and Design

By James R. Kirby, GAF.

Building science is the study of the effects of heat, air, and moisture (vapor and liquid) on the building enclosure.

The design and construction industries are increasingly using building science concepts to design and construct long-lasting, high performance buildings.

The concepts are not new, and have been understood by some in the building and design communities for decades. However, for many designers, it’s a shift from traditional practice that emphasized form, aesthetics, and programmatic requirements over building science fundamentals. Understanding the complex nature of building enclosure performance and the science behind it will have a positive impact on how buildings are designed and constructed, and endure; and it assists architects in mitigating the risks of design-related building failures.

Understanding building science

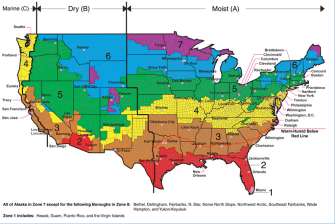

Building science is the study of the effects of heat, air, and moisture (vapor and liquid) on the building enclosure. It involves an understanding of building performance within specific climate and environmental conditions (as shown in the ASHRAE climate zone map in Figure 1) from a systems perspective rather than as a collection of individual unrelated components. Building science can be used to mitigate or prevent damage from air and moisture infiltration and high winds and to improve the energy efficiency, durability, and long-term performance of buildings.

Figure 1: ASHRAE Climate Zone Map Showing Different Climate Zone Conditions in the U.S.

Second law of thermodynamics

The fundamentals of building science are found in the Second Law of Thermodynamics.

- Heat flow is from warm to cold.

- Moisture flow is from warm to cold.

- Moisture flow is from wet to dry.

- Air flows from higher pressures to lower pressures.

- Gravity acts down. (Think Isaac Newton’s apple tree)

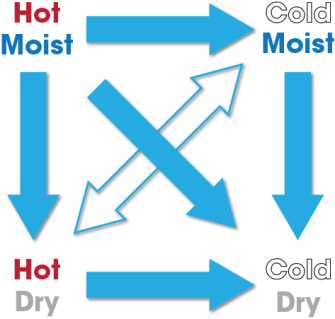

In short, energy, air, and moisture are exchanged between two systems until a state of equilibrium or balance is achieved. See Figure 2.

Figure 2: Graphical depiction of the Second Law of Thermodynamics as it relates to building science

The struggle with water

Of the many challenges that a building enclosure faces, water represents the greatest continuous threat. In other words, while high-wind events, impacts, and fires have to be considered in design, it is ongoing water infiltration that is of primary concern to building designers.

There are four primary moisture transport mechanisms to consider when designing a building’s enclosure: bulk water, capillary water, air-transported water, and vapor. The most obvious and impactful is bulk water, such as rain. Buildings need to be designed to efficiently shed or manage liquid water and the design community generally does a good job of properly detailing the building enclosure to achieve that goal.

Next is capillary action, which primarily deals with below grade moisture infiltration through pores and small cracks in foundations and the intersections of above- and below-grade systems. The design community does a good job of properly detailing the building enclosure for capillary action as well.

The last two—air-transported water and vapor diffusion—have an effect on the performance and durability of building enclosures, but the materials and designs used to control air intrusion and reduce vapor diffusion are often less obvious.

Figure 3: 1) Bulk water, 2) Capillary water, 3) Air-transported water, 4) Vapor diffusion

Air leakage can carry 10 to nearly 100 times the amount of moisture when compared to vapor diffusion, which is why the IECC, since 2012, requires the use of air barriers in building enclosures. Gaps and discontinuities in air barriers within the building enclosure allow air flow, with its associated moisture. This moisture intrusion can be problematic!

Vapor diffusion through building materials is much less impactful than air intrusion and its carried moisture, and for this reason, the codes are nearly silent on the use of vapor retarders in roofs. The need for vapor retarders in certain climate zones and high humidity environments has been historically recognized by the design community, yet oftentimes these vapor retarders were beneficial because, unknowingly, they also acted as an air barrier. However, because of a lack of building science knowledge, vapor retarders have not always been incorporated into designs correctly, causing building damage.

Air movement within the building enclosure

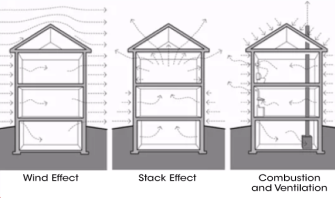

Controlled and uncontrolled interior air pressures from wind, stack effect, and HVAC systems often combine to create air flow across the building enclosure. See Figure 4.

Figure 4: Processes that create air-flow across the building envelope. SOURCE: Building Science Digests, BSD-014: Air Flow Control in Buildings, John Straube, October 15, 2007

Wind exerts pressure on the building enclosure. On the windward side there is positive pressure, and on the leeward side there is negative pressure. The stack effect is about warm air rising, increasing pressures higher up in the building. There are also mechanical-related pressures due to forced air systems. These pressure differentials create air and moisture movement within a building and through, or across, its enclosure. Proper placement of the thermal layer and air/vapor control layers can help prevent moisture intrusion into the building enclosure. Building science can provide ways of predicting moisture movement within an enclosure and therefore help determine if a certain design configuration will minimize or block vapor and moisture intrusion and retention.

The importance of managing uncontrolled air flow, and the moisture it carries with it, cannot be overstated. The air’s ability to hold moisture is dependent on its temperature. Warm air holds more moisture than cold air, and when warm moist air encounters a cold surface, the air will cool (and its ability to hold moisture will decrease) and the excess moisture will condense on the cold surface. This is why air barriers are best located on the warm side (in winter) of the dew point; proper placement of air barriers limits the risk of condensation on surfaces within the building enclosure. For roof systems,installing the vapor retarder as an air barrier (i.e. sealing all penetrations and transitions) allows us to address vapor diffusion and air transported moisture.

Thermal performance

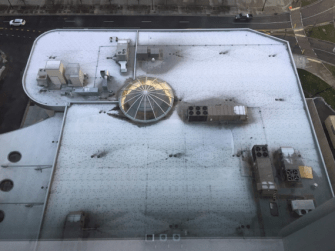

Thermal bridges have an impact on the thermal performance of our buildings. In particular, fasteners can play a significant role in reducing the effective R-value of our building enclosure’s thermal layer. Figure 5 shows roof fasteners acting as thermal bridges, melting the snow on the roof due to conductive heat transfer. Interestingly, the energy codes don’t recognize the impact of thermal bridging from fasteners on continuous insulation systems.

Read more about the importance of R-Value Optimization and how adhered roofing systems can be cost competitive once long-term energy efficiency is factored in.

It is important to be cognizant of the negative effects that moisture-laden air, water vapor, and thermal bridges have on long-term building performance and incorporate preventative measures into our design to mitigate risk. This requires a strong understanding of the building science principles.

Figure 5: Photo of a rooftop after a light snow with snow melt at each fastener.

Are minimum codes enough?

Architects can, and often should, design beyond the minimum code requirements within the IBC and IECC in order to improve the durability and longevity of their buildings. This is especially important with our changing climate and the increased frequency and magnitude of storms and weather events. Designing building enclosures from a building science perspective can be an effective way to reduce condensation potential and moisture damage, reduce wind-related roof failures, and provide an energy-efficient thermal layer. The result can be a high performance building enclosure!

Designing with building science in mind

Today, architects are increasingly leveraging new technologies to design buildings of greater complexity. New materials are being incorporated, and traditional materials may be used in new ways. For example, the use of air barriers in roofs and walls is now mandated, so understanding how they can affect condensation potential is critical. The introduction of thermal insulation, tighter building enclosures, and increased mechanization of our interior environments means we have to change the way we approach our designs and consider buildings as holistic systems rather than as individual parts.

We increase the potential of long-term performance, improved durability, and energy efficiency when building science fundamentals are incorporated into our designs. And these design ideas can align with an architect’s aesthetic vision. Can the owner’s and occupant’s goals be met if the building isn’t performing correctly, not only initially but for the duration of its expected life?

What can happen when buildings aren’t designed or constructed in accordance with sound building science?

- Structural failures

- Building enclosure material degradation. See Figure 5.

- Biological growth

- Reduced building life expectancy

Figure 6: Photo showing material degradation because of moisture intrusion.

(Image courtesy of Phil Dregger)

Practical ways to incorporate building science into designs

Designing a building in accordance with building science fundamentals is just the first step. Ensuring that the as-constructed building aligns with the architect’s design intent is also important. The following are some steps the architect can take to meet these goals.

Design phase:

- Understand the impact of heat and moisture transfer through the building enclosure; Hygrothermal analysis[1] may be useful with more complex designs. Remember the Second Law of Thermodynamics as it relates to building science.

- Calculate temperature gradients[2] across the building enclosure to determine the need and correct location of a vapor retarder/air barrier within the building enclosure.

- Account for and , such as hail or wind-blown debris

Construction document phase:

- Include the air barrier and the vapor retarder (when required) in the drawings.

- Identify specific components of the code-required air barrier system in the drawings.

- Include specification sections that are project, system, and material specific.

- Provide details of the vapor retarder (when required), insulation, air barrier system, and weather-resistive barrier transitions (e.g., roof-to-wall) to ensure continuity and avoid the ‘”by others’” conundrum.

Bidding phase:

- Understand the risks of value engineering and life-cycle cost implications (initial versus long-term costs).

- Clearly communicate why components of the design are critical for long-term building performance and energy efficiency.

Construction administration phase:

- Review the project submittals to ensure that the specified products and systems are properly incorporated into the project and that alternates are not substituted inappropriately.

Partnering with experts

The most successful buildings will not only meet the architect’s aesthetic vision, they will be well-functioning for the occupant as well as long-lasting, durable, and energy-efficient. Building enclosure consultants who specialize in building science and energy modeling may be a valuable addition to a project team tasked with navigating the gap that sometimes exists between design and science.

It is also important, during the design and specification process, to work closely with product manufacturers, like GAF, that have experts on staff who understand building and roofing science, to ensure that the correct products are used, and that systems as designed will provide the expected performance to help lower an architect’s risk.

Learn more about how GAF can help during the design process.

Original article source: GAF

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In