An Introduction to Thermal Bridging

By IKO.

Understanding and preventing thermal bridging in commercial buildings.

A thermal bridge is a pathway that heat uses to get in or out of a building, bypassing the insulation layer.For example, your roof may be well insulated, but a metal plumbing vent that passes through the roof and its insulation can carry heat in or out of the building. Heat moves not just through the air space in the vent, but through the metal itself. If it’s winter and you’re trying to keep your building warm, a cold plumbing vent will let heat escape outside. This reduces your building’s energy efficiency, makes it colder and forces the occupants to increase their heating to compensate.

The heat escaping out of the building through the metal pipe, could produce condensation with the temperature change.

Depending on whether you’re trying to keep heat in or out of a building, a thermal bridge might be referred to as a cold bridge, heat bridge, or a thermal bypass. No matter what you call it, anyone who owns a building or works with the building envelope must account for thermal bridging. If you can reduce thermal bridging, your building will be more energy-efficient, will keep conditioned air inside longer and will cost you less in heating or cooling.

Why is Thermal Bridging Important?

Thermal bridging is a fundamental concept of heat transfer, and it has certainly affected buildings for decades, so why has there been so much emphasis on thermal bridging lately? As building insulation becomes more efficient, thermal bridges become more significant obstacles. Previously, heat would seep out of a building’s walls as well as any thermal bridges. Now that walls are more adequately insulated with interior insulation, the heat has no choice but to find and use bridges instead.

This is very unfortunate for passive buildings and energy-efficient buildings. While the insulation used in the building has a specific R-value, a thermal bridge will reduce the actual R-value the building (as a whole) achieves. As a result, many energy efficient and green building standards have started to call for a building’s actual R-value, called the effective R-value, rather than assuming the building automatically achieves the insulation’s R-value. This is a more demanding standard to achieve.

What are the Impacts of Thermal Bridging?

It’s not just green building owners who will be affected by thermal bridging. Instead, this phenomenon has several impacts on the overall quality and longevity of any insulated structure.

1. Loss of conditioned air: The primary impact of a thermal bridge is that it will allow conditioned air to leave the building, losing heat in cold weather and gaining heat in hot weather. This may have a significant impact on the comfort of the occupants, not just in the overall temperature they experience, but also when they touch colder or hotter than average walls and floors. If your building must maintain a certain temperature, whether it’s room temperature for people or a specific temperature for stored goods, a thermal bridge can make it more expensive to maintain that temperature.

2. Loss of energy-efficiency: A building that relies on insulation to achieve its energy-efficiency standards may be thwarted by thermal bridging. Design and construction choices that encourage thermal bridging may cause the building to fail to qualify for energy standards, achievements, and awards.

3.Increased condensation: As thermal bridges allow for warm air to mingle with colder air, they frequently encourage condensation. This effect is more pronounced in areas with high humidity than in areas with low humidity. When condensation occurs in a building, it has many impacts on air quality. It may allow for mold growth and negatively impact the health of building occupants, especially those with breathing problems. Constant dampness may also cause damage by ruining drywall, furniture, and other items.

4. Interstitial condensation: Condensation from a thermal bridge may not end up on the interior of the building. Instead, it may collect in between the walls and other building elements. This is called interstitial condensation. It has serious impacts on the longevity of the building in question. Wherever moisture collects, rot and rust may follow. If you cannot see the condensation, because it is in the walls or pipes, you will not fix the damage it causes. When left unchecked, rot and rust can cause damage to your building.

5. Reduce insulation effectiveness: If you purchase high-end insulation, you want to make the most out of it. However, serious thermal bridging problems can interfere with the effectiveness of new insulation, unless that insulation blocks the bridge. As a thermal bridge is more heat conductive than the insulation you place next to it, the heat will continue to use the bridge. You will likely see diminished returns from new insulation unless you correct the underlying thermal bypass.

Where can Thermal Bridging Occur?

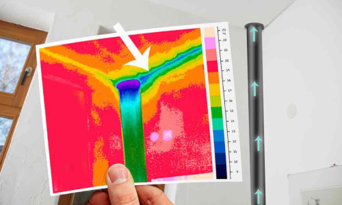

The impacts of thermal bridging are quite important. Naturally, you’ll want to discover if your building is suffering from it. A professional equipped with a thermal imaging camera can capture a map of where heat is escaping or intruding in your building.

Where will the thermal bridges be? Anything that penetrates the building envelope can offer heat a bridge out or in. You may find a thermal bridge in any of these areas:

-

Spots where the roof and wall connect.

-

Spots where the floor and wall connect.

-

Pipes, cables, and vents that puncture the building envelope.

-

Window and door openings or framing.

-

Steel wall ties & other metal fasteners.

-

Balconies and their supports.

-

Wall studs, whether wooden or not.

After making a heat map that exposes these thermal bridges, a professional can also calculate your building’s thermal bridge coefficient. This value measures how significant your thermal bridging is. However, it is quite unlikely you’ll have no thermal bridging at all. Instead, a coefficient value of 0.01 means that your building is about as thermally secure as it can be.

The Types of Thermal Bridges

The severity of your thermal bridging isn’t just about location, it’s also about type. Thermal bridges can be classified into three main types, each with a different impact on your building.

The three types of thermal bridges are:

1. Linear thermal bridges: The impact of a linear thermal bridge is larger, the longer the bridge is. This type of thermal bypass occurs where two linear parts of the building intersect, including at corners, parapets, etc. The example below shows a balcony slab intersecting the wall of the building. This will cause a linear thermal bridge.

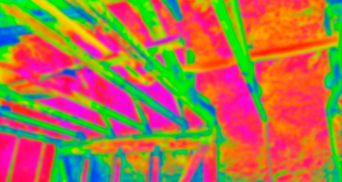

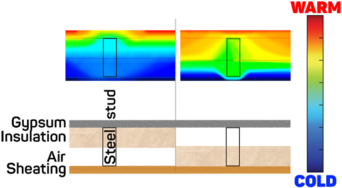

2. Assembly thermal bridging: Also called clear wall thermal bridging, these thermal bridges are part of the flat wall, not the corners or junctions. They may include framing or other parts of the assembly. The example below is a thermal image of metal wall framing. Assembly thermal bridging is usually accounted for when buildings are being tested for their energy code compliance.

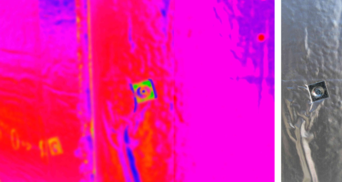

3. Point thermal bridges: These are thermal bridges that occur at small points, such as an improper insulation fastener. Point thermal bridges may sound the least harmful, but size is not the most important thing about a thermal bridge. Think of a thermal bridge as a hole in a balloon, it may be small, but it will let out a lot of air. Small thermal bridges allow for a lot of heat transfer, especially when they are repeating. The image below shows improper insulation fasteners acting as thermal bridges.

All three thermal bridge types may be repeating or non-repeating. A repeating thermal bridge will be found regularly throughout the building, such as the framing. Non-repeating thermal bridges don’t appear in a regular pattern throughout the building. Windows and doors are a simple example. We’ll discuss the strategies you can use to reduce all three types of thermal bridging below.

How to Prevent Thermal Bridging

Preventing thermal bridging starts with your architect. Certain design decisions can prevent common thermal bridges in the first place. Architects must consider shelf angle, structural choices about how to mount the windows and doors and whether to include parapets and other potential heat-bridge features. It’s wise to talk to your architect about their experience and how they plan to reduce thermal bridging. You may also consult with a dedicated energy efficiency expert. You can find these professionals through Energy Star®.

If you’re concerned about an existing building, you may find it a challenge to reduce thermal bridging. Especially in multi-level buildings, thermal bridges are often repeating, which means it will take significant work to fix them all.

Though it may be challenging to reduce thermal bridging in a preexisting building, there are several solutions you can implement to do so. Options include the placement and type of insulation and fixtures. Before you consult with your experts and decide which strategy is best for your building, it’s important to understand all of your options to stop thermal bridging.

Thermal Breaks & Thermal Bridging Solutions

Imagine a thermal bridge as the Brooklyn Bridge and the heat as the cars on the bridge. If so, a thermal break is a toll booth on that bridge, a toll booth that’s always closed. In construction terms, a thermal break is a layer of insulating material (or just a material with better thermal resistance) in an object or building feature that might otherwise act as a thermal bridge. For example, thermal bridging in windows is common, and the glazing is a thermal break intended to reduce the travel of heat from one pane to another.

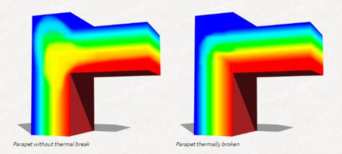

Thermal breaks can be installed during construction or afterwards. Recently, building owners have begun to install thermal breaks in parapets. Parapets are the low walls along the edges of roofs. Usually, these walls act as linear thermal bridges, pulling heat out of building below. You can see in the thermal image below that the presence of a parapet reduces the temperature of the interior of the building, where there’s yellow.

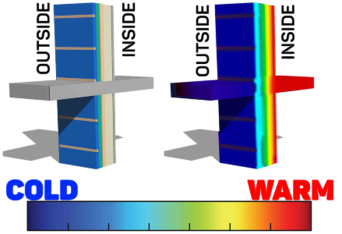

To break this thermal bridge, you must install a layer of installation not inside of the building, but into the parapet where it joins the roof face. This way, the bridge is blocked and significantly less heat can move through it. The image on the right shows how well the heat is retained after the thermal break is installed. The break was installed where the image shows new dark blue.

Thermal Bridging Insulation & Installation

If your building has a poor U-value, improperly installed installation, or inadequate insulation, may be contributing. Gaps between the insulation, poor fastener choice, or poor choice of tape, can allow for thermal bridges between the sheets of insulation.

In our insulation fastener guide, IKO recommends using thermally broken plastic washers to help reduce the effect of thermal bridging through the fastener. You may also choose a fastener that is itself thermally broken. Lastly, the tape your contractor uses to hold the sheets together can also be thermally broken.

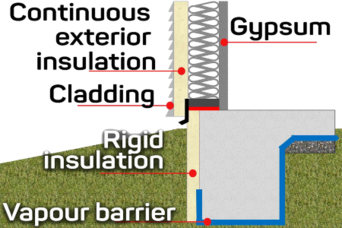

Continuous Insulation

As thermal bridges can occur throughout the building envelope, one strategy to combat them is continuous insulation. This is not just your standard procedure of cutting insulation tightly to fit into the walls and taping them together, though that is important to ensure an insulation’s effectiveness. Instead, continuous insulation is installed on the exterior side of the walls, so it isn’t broken up by wall components, except service openings and fasteners.

Placing insulation on the exterior of the wall doesn’t seem like it would make a significant difference, but testing reveals that it does. The image above shows the difference in heat retention between two walls. On the left, the insulation pressed against the internal sheathing. On the right, the insulation pressed against the exterior gypsum.

Just as with the parapet, it’s desirable to cut off the thermal bridge at the most exterior point available in the wall. It’s best to keep the cars from getting on the bridge, rather than allowing them to collect at a blockade on the other end.

In a multi-story building, interior insulation cannot be continuous. In order to meet building code standards that require continuous insulation, as many local codes now do, the insulation must be installed over wood studs and before sheathing.

Exposed slabs can act as thermal bridges that can increase a building’s U-value by 71 percent, especially when repeating. Continuous insulation is the best strategy to combat this.

For thermal bridging insulation, Polyiso rigid foam insulation is best. IKO’s polyiso rigid foam products include Ener-AirTM & Enerfoil® Wall Insulation. Both are designed to be on structural sheathing with high thermal R-values, precisely what you need to limit thermal bridging. Both products may also be retrofit into existing buildings, see the insulation installation guide for more details.

If your building calls for masonry, you must also install masonry ties. Both of our insulation types are suitable for masonry ties. Further, choosing a tie with as low a thermal transmission rate as possible will help reduce thermal bridging.

Insulated Building Slab

The building envelope doesn’t just go up to the roof, it also goes into the slab. Concrete slabs can act as thermal bridges. Many cold-weather areas, particularly in climate zones four and higher, require you to insulate your building slab. It’s also best if the continuous exterior insulation and building slab insulation come into contact with one another, so no thermal bridge can develop in the gap between them.

This way, you’ll have entirely continuous insulation, and the best protection from thermal bridging available, at least for now.

Building Codes for Thermal Bridging

When it comes to thermal bridging, building code change has been slow. It is often challenging to measure the effect of thermal bridging, which makes it challenging for professionals to make standards around them. In fact, before the advent of 2D and 3D computer models, it was almost impossible to analyze where thermal bridges were and what effect certain construction decisions may have on them.

For now, the International Energy Conservation Code (IECC) requires continuous insulation and thermal breaks on new buildings. These changes should help buildings meet the IECC’s new minimum U-Factor. The U-Factor is the measure of how much heat flow can transfer through the building as a whole. It’s a cumulative R-value. New techniques for measuring U-Factor are better at accounting for thermal bridges.

Your local codes may be more specific about how you should combat thermal bridging. You’ll also find that codes differ by nation. The likelihood of winter humidity over 35 percent in Canada is quite low, meaning it is a challenge for thermal bridging to create much condensation. Thus, the local building codes in the country generally have less stringent thermal bridging codes as compared to areas in the United States with higher levels of humidity.

Even if you have met your local building code obligations, these strategies may not be enough to meet your personal goals for your building.

The Future of Thermal Bridging

Thermal bridges are becoming ever more important aspects of building construction. You can be sure that building codes will continue to change to take them into account. Reducing thermal bridging will continue to challenge architects, manufacturers, and everyone involved in the building envelope.

Reducing your building’s thermal bridging will help you maintain air quality, keep energy costs low, and increase environmental efficiency.

Get more information on becoming an IKO commercial installer.

Original article source: IKO

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In